Though CNC machine is usually related to large-scale manufacturing, they are equally handy when used on desktop levels. Of course, the CNC routers made for hobbyists do not need the type of components used on the industrial level CNC machine. But, regardless of how downsized they are, a CNC router still need motors for driving the motion systems. And, this is where the CNC stepper motors come into the picture.

The CNC stepper motor, also known as the stepping motor or step motor, is a kind of brushless DC electrical motor that provides greater precision compared to a regular DC motor. The stepper motor is able to break down a complete revolution into a couple of equal steps to make it suitable for the operations where precise and small movements are needed.

The part is that the stepper motors are simpler in their design and easier to use, which makes them immediately a better option for the people who are new to the world of CNC machining or woodworking. And, on that note, take a look at the detailed review of the top ten stepper motors, along with a few tips on how to choose the right one.

Table of Contents

Stepper Motors for CNC

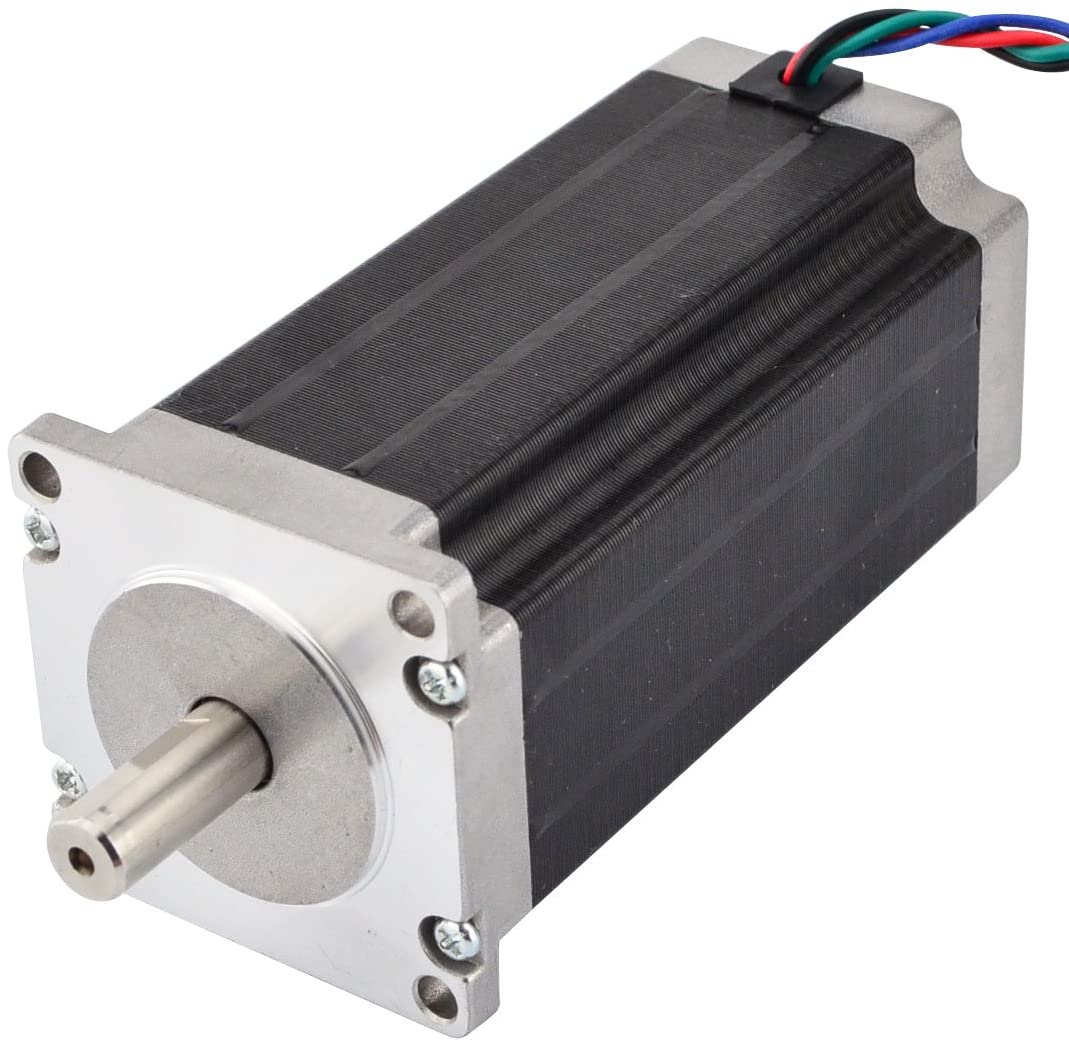

1. Nema 23 CNC Stepper Motor : Stepper Motor Overall

One of the stepper motors you can use for all kinds of projects, such as 3D printer and CNC router, this Nema 23 stepper motor is actually value for money. It is great for all kinds of CNC applications like RoBo 3D, Rostock, and Prusa. Think of the times when you don’t get the main components on buying a CNC kit. This motor can be a lifesaver in such situations. A perfect stepper motor for the hobbyists.

PROS | CONS |

|

|

2. TOAUTO IHSS57-36-20 Nema23 Stepper Motor with Driver : Alternative to Nema 23

The inclusion of Position Tracking Technology, in this stepper motor, is remarkably helpful in overcoming the synchronization troubles. A Position Encoder has also been integrated to make it function like a closed loop system, which ensures automatic position correction. The high-efficiency and low heat motor driver is definitely a plus. It is also accurate and smooth in its operations because of the filtering technique and the Encoder feedback algorithm. You will not have to deal with the usual vibration and noise issues.

PROS | CONS |

|

|

3. Quimat Nema 17 Bipolar Stepper Motor : Budget Pick

If you are looking for a Nema 17 bipolar CNC stepper motor, then this product from Quimat will not disappoint you. It works on both 9V and 12V DC power supply, but it is better to use the former. The product actually runs at a higher amperage compared to what you will find for most stepper motors of this size. The study and durable construction means that it will last you for a long time, and it’s perfect for the hobbyists.

PROS | CONS |

|

|

4. Heechoo Worm Gear Nema23 Stepper Motor : Premium Pick

If you are a hobbyist that is looking for a good CNC stepper motor at an affordable price, then you should look no further than this one from Heechoo. You can use it for a wide range of CNC Router works, like lathe, milling, engraving, and so on. The power is good enough for your DIY woodworking projects and the torque does not disappoint either. The worm geared factor is a great addition to the stepper motor.

PROS | CONS |

|

|

Other Great Picks

5. STEPPERONLINE Nema 17 Bipolar Stepper Motor 2A

This one is yet another commendable product from StepperOnline that comes with a very powerful Nema 17 motor. The motor is great and it can drive all kinds of CNC machines and 3D printers. You can drive this for one ampere and 36 volts, and it will still only feel warm instead of hot. The durability and strength that you get from this one is so amazing that you will not even need to consider getting a Nema 23.

PROS | CONS |

|

|

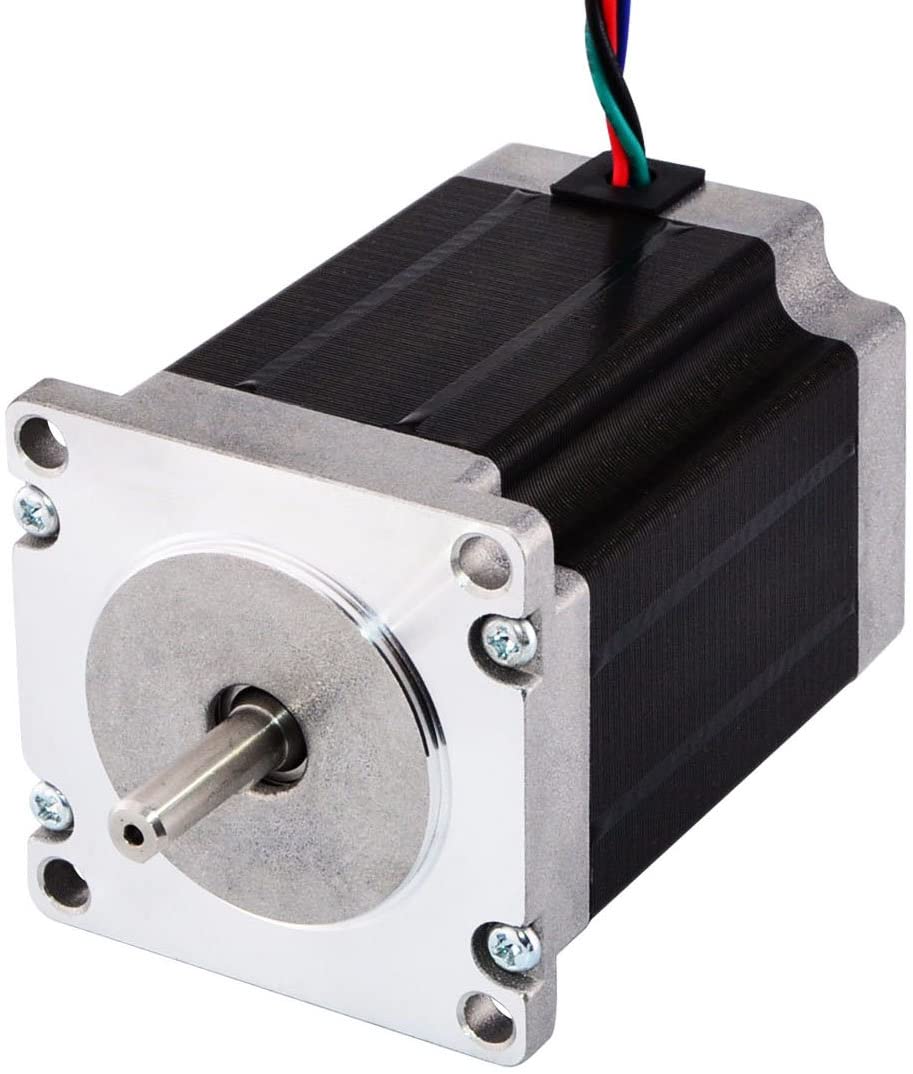

6. STEPPERONLINE Nema 23 Stepper Motor

This is one of the most powerful Nema 23 Stepper CNC Motor that you can own, and once you figure out the specs, there is no stopping it. The motor is powerful enough to direct drive an eight inch pneumatic terrain tire. It comes with enough torque to make sure that your work goes smoothly and without any breaks to it. The fact that you get all these features at a great price point is definitely a major plus.

PROS | CONS |

|

|

7. Usongshine Nema 17 Geared Stepper Motor

This geared stepper motor will give you more precision than you can ask for, and that’s the part of it. You get one revolution of the output shaft for 5.18 revolutions of this stepper. Thus, the maximum RPM of the output shaft for this one is around 350 to 400 RPM. It is easy to set up and use. The speed and the torque are both really good to work with.

PROS | CONS |

|

|

8. STEPPERONLINE Low Current Nema 23 Stepper Motor

The finest feature of this CNC stepper motor is that it has a high torque but runs on low current. It works great for all the three axes, and the power is good enough to get your work going. You can use it with any medium current handling stepper driver. The instructions are precise and clear, and any hobbyist can put it together all by himself. However, this is not a small motor, so think of your space constraints before purchasing it.

PROS | CONS |

|

|

9. STEPPERONLINE Bipolar 2A Nema 17 Stepper Motor

If you have been thinking of replacing your Nema 17 with a high-end Nema 23, then stop and take a look at this one. This has enough power for a Nema 17 to make you forget that you ever thought of buying Nema 23. The high torque ensures smooth operation and greater precision. The wires might not be well-documented but they are of good quality.

PROS | CONS |

|

|

How to choose a stepper motor for CNC Router?

There are a couple of factors that you need to consider when choosing a stepper motor for your work. Here is a brief overview of those factors that you need to check before making the purchase. These are also the factors that we have considered in choosing the ten stepper motors for you.

Torque rating

Stepper motors get rated according to their holding torque in oz. /in (ounces/inch) or Newtons per centimeter or meter. For instance, a stepper motor with Nema 23 might have 175 oz. /in as torque. This means it has the ability to hold 175 ounces on one arm of one inch length attached to motor shafts, which refers to the holding torque. It is used in comparing motors. You should also note the amount of current the motor draws and the voltage needed by it to work.

Unipolar and bipolar

Stepper motors are unipolar or bipolar, which refers to the way the coils remain connected. Without getting into technical details, it suffices to say that bipolar motors are the ones used the most widely. These come with a high torque output because of the way the coils remain wired. Though switching the coils requires highly complex circuitry, that’s not an issue as the driver modules are here to do that for you. Wiring the coils in a particular way can turn unipolar motors into bipolar ones. All stepper motors for hobbyists are bipolar.

Power supply

The power supply has to deliver the current and voltage for your selected controller and motors. Going for higher current will not hurt but the controller’s voltage and yours has to match. For instance, say you have 4 x NEMA 23, with 2.8 amps and 2 amps are needed by the controller. So, (4 x 2.8) + 2 amps is equal to 13.2 amps. If you multiply that by twenty-four volts to get Watts, you will have 316.8 W. They are either rated by Watts or Amps, so here you can use a 350 Watt 15 amp supply.

Types of machines

Selecting a stepper motor also depends a lot on the kind of machine you are going to build or have and the type of material you are about to cut. So, here is a brief outline on the approach you need to take for selecting motors for a router and foam cutter.

1. For the CNC routers:

A good idea is to get Nema 23 with 175 oz. /in and upwards, if you do not have a machine that is small like a CNC engraver. It is generally used to make PCB (Printed Circuit Boards), and the description mentions that it’s made for soft materials. However, you can get Nema 17 too, if the power and torque are good enough. Keep your budget and your needs in mind while choosing a stepper motor from our list, and it will be easy for you to select the right product.

2. For the CNC foam cutter:

Cutting foam using a hotwire foam cutting machine is called cutting by radiance, and it actually melts and not cuts the thing. So, the feed rate and temperature has to be correct for the load on the motors to amount to nothing. The weight of the moving machine parts gives the load, and you will have to keep that in mind while making the purchase.

Conclusion

Now that you know the options for the stepper motor for cnc, you can go ahead and start to build your own CNC. As a hobbyist you are required to look for the different options required for a DIY CNC machine and we have worked and researched with multiple woodworkers and Bill Baum himself to figure out the options available.

Interesting article, tho I still have this question, I’ve been at this game for many years, with some success in adapting my old Bridgeport to a CNC machine, or at least took out a lot of the hand cranking. When I started, there wasn’t much out there to lean on for info, so I bought 3 NEMA 34 motors, of around 900nm of torque, unipolar, and the appropriate drivers and PS, and it did work, I now have bought 2, bipolar motors and drivers, with encoders, I presume about the same torque, the Z axis wasn’t really needed, so I’m not going to worry about it for now. My question is, are these motors capable of doing what I want, they seemed like they were, I was making parts out of aluminum, cast and billet, but I feel like going to the encoder motors will give me more accuracy, the return trip was not always on target, close but no cigar, am I expecting too much, burning money, or on to higher accuracy, with enough torque? Hint, for you guys just starting, we had an awful time getting it smooth, you could watch a hand crank “stumble” about every second, a quick call to the gent who wrote the program asked if the computer had ever been used on line, and I said yes, and he told me how to make it quit, but I don’t remember now, plus he had one wire out of place between the PC and the break out box, that took some figuring out also. Not all plug and play. Thanks. Bob

PS, I drove them 2 to 1 with cog belts, not knowing any better, I’d say that part was pure success!

We will appreciate it if you provide us with details about the stepper motor.