A CNC mill can be quite helpful and productive if you know the right use of it. Choosing the CNC mill can become quite tricky since these machines are usually very expensive. It is very important to know your requirements beforehand and that’s where our buying guide is going to help you.

You can fall in many different categories of people interested in woodworking. You could be a hobby woodworker or a professional woodworker. We’re all bound by different budget. In this article, we’ve made sure to cover all the CNC mills that come under 10k and there are some that even come under $5,000.

We’ve personally tested and asked our friends in the woodworking community for their views on the products mentioned below. If you have questions on how to set them or what’s the fit for your purpose. Do reach out to me and my team will personally help you choose the CNC mill under 10000.

Table of Contents

What does a CNC mill do?

A CNC mill is designed to perform multiple functions of most materials. A CNC mill can cut through large sheets of aluminium with precision. It can be used to cut through a complex design and perform simple applications like milling and drilling very easily. No matter how complex a shape or a hole is. You just have to feed the machine with the right data and it’ll perform the function.

A milling machine also works very much similar to the CNC mills but they are more preferred for heavy woodworking or metalworking. Also take a look at some of the desktop milling machines

What type of materials does CNC mill operate on?

A CNC mill can be used to perform operations like drilling and cutting on multiple materials like aluminium, plastics, steel and iron. Though what’s important is the purpose. If you wish to create a design that is both complex and expensive in terms of production and resource then you need to use certain modifications to get the desired result.

Difference between a CNC router and CNC mill

The major difference between both the CNC router and mill is the type of material each cuts down. A CNC router cuts softer material while a CNC mill cuts down all different types of material like wood, plastics, aluminium and others. A CNC mills is made such that it can cut through metals very easily. That’s also a reason why a CNC mill is heavier and costs more than a CNC router.

Many a times, it also depends on the purpose. If you wish to cut softer materials into large sized sheets then you precision and that’s when a CNC router can’t do much for you.

There are a lot of CNC router that specialise in cutting aluminium you can check them out here.

In such a case, you better use a CNC mill that outperforms a CNC router when it comes to accuracy. A CNC mill has an average RPM of 1000 while a CNC router has 18,000 RPM.

CNC Mills under $10000

1. Tormach PCNC 440

Tormach never fails to deliver and the PCNC 440 is another success story that lets you shape and engrave the toughest metals. While most CNC mills are targeted towards various materials, the 440 excels in cutting metals. However, you can also use it for cutting wood, plastics, composites and more.

The 0.75 HP R8 spindle works its magic at a phenomenal 10,000 RPM. With its Poly-V Belt transmission system, you get to cut through even titanium like butter. However, the really astonishing facts about this milling machine is its size. Due to Tormach’s compact form factor, it fits in anyone’s workstation.

Even if you don’t have a large workstation you can a setup your woodworking workshop in a basement with the help of this guide.

But that doesn’t mean you have to limit your work options. At both the X and Z axes, you get a generous 10 inches of travel while the Y-axis allows 6.25 inches of travel. With a maximum clearance of 11 inches between the table and spindle nose, you get plenty of room for creativity.

PROS | CONS |

|

|

2. Stepcraft D.840 CNC

The D.840 Desktop CNC has reliable German engineering behind it and an active social media community that assist everyone from newbie hobbyists to experts. The strength of the Stepcraft machine lies in its versatility. You can change attachments within no time and switch milling to laser engraving, 3D printing and much more.

For the worktop, you can get the regular one made from HPL material or opt for the aluminum T-slot table for a small increase in the price tag. In terms of build quality, D.840 CNC doesn’t lose out to its peers despite its moderate pricing.

You get long-lasting stepper motors from Nanotec, highly precise lead screws from Switzerland and other tiny details that speak about its excellence in quality. Read the detailed review of Stepcraft 840.

PROS | CONS |

|

|

3. Tormach PCNC 770

The PCNC 770 by Tormach uses an R8 spindle along with a 5/8-inch, three-slot setup, which is common enough so that people who use a manual drill can employ most of their existing tools with PCNC 770. Having been constructed in China, the pricing of the product is about one-third of the mills made in America, while still ensuring that it is easy to use and strong enough to withstand prolonged usage.

Apart from CNC mill there are several top quality CNC router manufactures in china, that may want to check out

The controller of Tormach PCNC 770 is preconfigured with Artsoft Mach 3 software – which is the industry standard. It means that you can start working with the mill right out of the box. Although the PCNC 770 itself is three-axis, you do have the option to add a fourth axis. This allows you to employ keyways and undercuts for full-blown 3-D milling.

Tormach PCNC 770 is designed to fit neatly into a small CNC workshop and perform all the functions. It can withstand high loads, dampen milling vibrations, and comes with low-friction PTFE filled Acetyl copolymer bonded surfaces. Such surfaces reduce the chatter of the machine by eliminating the stick-slip friction.

Tormach PCNC 770 combines all the rigidity and power of an expensive CNC milling machine in addition to providing the features that make a benchtop machine attractive – minimum input power requirement and portability. It comes with superior wear resistance for lifelong use.

PROS | CONS |

|

|

4. Tormach PCNC 1100

Like all Tormach products, the PCNC 1100 makes it easy to build your CNC shop the way you like. The superior design and impeccable engineering of the machine made it possible to combine performance with affordability. The PCNC 1100 comes with a precision driven approach to cut even the toughest of materials like butter, whether it is stainless steel, titanium or pre-hardened tool steel.

Additionally, Tormach PCNC 1100 is capable of milling these materials at or near their recommended cutting speed. For instance, for fast metal removal of 6061 aluminum, the machine runs a ½” diameter 2 flute cutter at the rate of 18 inches per minute and 3000 RPM, which results in a surface speed of 390 SFM.

If you don’t need to remove a large amount of metal quickly, you can use a 3/8” cutter with 4000 RPM to achieve the same surface speed. Both the cutters can be easily used with the machine and the RPM falls well within the performance bracket of the PCNC 1100.

One of the things about Tormach PCNC 1100 is that you can customize it however you like. There are a wide variety of upgrades and add-ons available, and you can get everything from enclosures and ACT’s to Power Drawbars with the mill. Moreover, the mill comes with sliding dovetailed ways that can handle high loads and dampen vibrations, if any.

PROS | CONS |

|

|

5. Bolton Tools M4A

With its stellar reputation for creating mill/drill lathe combo tools that are durable and long lasting, the Bolton M4A is no exception. It comes with 3 axes and a 15-3/4” x 5-1/2” bench. The controls are generic CNC system with G-code programming that make it easy to operate. Bolton M4A comes with a transmission that adopts a DC brushless motor and can spindle at a variety of speeds. The 3 axes are connected to each other with the help of a step motor and ball screw, both of which then help it achieve feeding.

The handwheel offers excellent control over the X, Y and Z axes.The mill uses servo spindle which allows it to function at high precision with low noise. It has a rigid tapping function and a vertical control panel that makes it seamless to operate the mill. The M4A is especially well-suited for producing small parts, mould machining and for training. You can also buy an additional bench vice if you deem it necessary for your workshop.

PROS | CONS |

|

|

6. Taig 5019DSLS Micro Mill

The Taig Micro Mill comes with a complete setup which includes stepper motors, controllers, wiring and the software you will need to operate the machine.

Read this post to help you choose the cnc software for your machine.

This milling machine has an Advanced Digital Sync Lock Servo (DSLS) control, which uses latest microchip controller technology. Paired with 200 oz-in. stepper motors, it can provide you traverse speeds as high as 100 inches per minute with high motor torque. The structural design of the mill is engineered precisely with steel and aluminum and has the capacity to make a single pass cut of 1/8” inches depth in mild steel – all with a 1/8” end mill.

All the moving components are made of steel and hard anodized aluminum, along with the adjustable brass gibs. This ensures that it will last a long time and provide accurate cutting at all times.With a step resolution of 000125 inches and its fast, powerful, rugged functioning – the Taig is indeed one of the most economical desktop mills in the market right now.

PROS | CONS |

|

|

7. Sherline 12” Deluxe CNC Machine

The CNC package by Sherline includes a mill that is fitted with a saddle oiler, stepper motor mounts, and couplers on all 3 axes. It can be easily operated using an included computer system that has an Ubuntu Linux-based OS, along with the standard linuxcnc 4-axis CNC software already installed. Additionally, you will also get a keyboard and mouse with this CNC mill, and a 4-axis driver board already installed in the computer. Attach the computer cables with all the 3 axis and you are good to go.

All you have to supply is a monitor. Pretty sweet deal, huh?Although it is great for a hobbyist, the Sherline desktop mill system is not dependable if you want to make a living out of milling. This product is great at making small parts out of aluminum, but it has a rather small envelope that might not fit bigger things. Moreover, the optional high-speed pulley tops out at the speed of 10,000 RPM – which may not be enough for engraving. There are also a lot of tilts and swings in the system that are easy to get out of adjustment. For engraving, you may have to add an air spindle attachment, but those come with an air compressor and that can be noisy.

PROS | CONS |

|

|

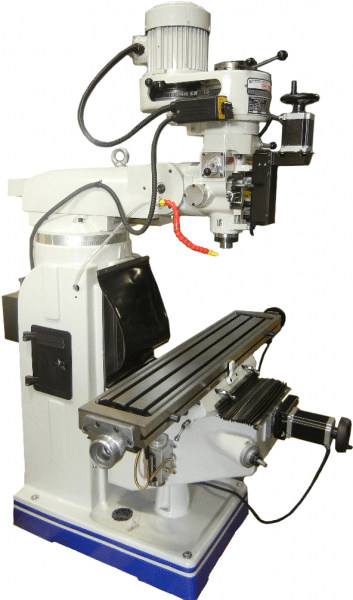

8. CNC Supra Vertical Knee CNC Machine

The classic vertical knee milling machine is made entirely out of cast iron and is easy to learn and operate. CNC Supra has full 3 axis movement that can be easily controlled with a computer variable spindle control. You will get the manual as well as CNC control with this product, and the X and Y axis have a ma travel of 34” x 115”.The Z axis on this CNC machine is quill driven to ensure that production is accurate and precise. If you are looking for an economical way to prototype your designs, this high-powered product is perfect for you. It is a versatile CNC – you can use it for product development, engraving, ceramic production, as well as teaching applications in labs and vocational schools. The product is ready to use right out of the box.

The controls are easy to master, and the setup process is quite simple. Help is available just a phone call away, and the customer support is simply excellent. All the parts of the CNC are built in the US, to ensure maximum dependability and superior quality. All in all – this product is an excellent knee mill for novices as well as those who are already experienced.

PROS | CONS |

|

|

9. Sherline 18” NextGen CNC Mill System

Fitted with a saddle oiler, couplers on all 3 axes, and stepper motor mounts – the CNC package is fully equipped to get started with right out of the box. You will also get a computer, keyboard and mouse, computer cables etc with this package to get your whole setup going. All you need to do is get a monitor.Sherline 18” comes with a powerful 90V DC motor and an electronic speed control that can handle all your precise production needs.

The mill base also has a leadscrew protection to ensure there is no damage to it during production. With a maximum clearance of 14” – this milling machine is ideal for production on a small as well as large scale.The spindle speed range for this machine is between 70 to 2800 RPM and can be controlled an electronic speed controlled. The machine can be used for milling metal, brass, plastics, aluminium and wood – although it is recommended to use a dust cover for the latter.

PROS | CONS |

|

|

Conclusion

Now, you have a list of all the CNC mills under 10k that are not only very good at what they do but each of them has a USP that sets them apart from the competition. You can pick anything as per your budget and if you are a hobby woodworker, better browse our how to section and get going with some amazing tutorials.

Hey mate,

Thanks for letting us know we will soon publish an article on the same.

Thanks again for the heads up!

This is the great article and very informative about CNC services.

Thanks for the sharing information

This article is wonderful